Wound management is a major healthcare issue in Bangladesh. The socio-economic impact of wound is huge for our country. A proper wound care and/or dressing product could help to reduce the infection, and thus, reduce the treatment time significantly. At BME, BUET we are actively working on the following aspects to enhance wound treatment.

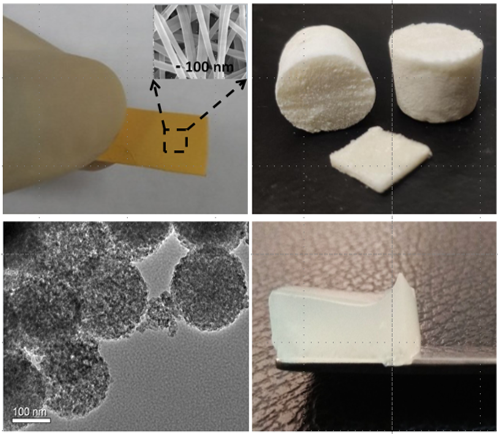

Nano-fibrous wound dressing:

Nano-fabrication technology, such as electrospinning has enabled us to fabricate non-woven fibrous matrix from sub-micron to nano range. We have successfully synthesized a range of natural and synthetic polymer based nanofibrous matrix [Mater. Res. Express 5 115407 (2018); Bull. Mater. Sci. 42, 171 (2019)]. We have further modified these nanofibrous matrix to get deliver controlled and/or on-demand antibacterial drug [J Drug Deliv Sci Technol. 55 101386 (2020); J Drug Deliv Sci Technol . 61 102297 (2021)].

Surgical Suture:

For closing a wound, surgical suture is considered as an unparalleled medical device. However, in a clinical setting, for an infected wound or in relatively infectious conditions, commonly available surgical suture may not be suitable. In this context, researchers at BME, BUET developed surgical suture which showed effectiveness against clinical pathogens.

Hydrogel:

Hydrogel, a three-dimensional (3D) cross-linked network, capable of imbibing a large amount of fluid while maintaining its structure. Hydrogels are extensively used in wound healing as it can maintain a moist environment at the wound site coupled with absorbing wound exudates. At BME, BUET we have successfully developed biopolymer based superabsorbent hydrogel [Cellulose 29, 5207–5222 (2022)]. We are also actively working on to develop advanced hydrogels for chronic wound healing.

Foam:

Foam structure has been using extensively in the field of biomedical engineering. Most of the foam structures are developed by freeze drying, phase separation, solvent casting and particle leaching. However, these processes are costly, temperature-dependent, and can leave harmful residues in pores. Here, we have developed gelatin based porous structure through a facile way, which could be useful for different clinical applications.

Hemostatic agents:

In order to save an injured person, we need to stop blood flow before hospitalization immediately. Moreover, to prevent bacterial inflammation on the wound site development of an antibacterial hemostatic is crucial. Available commercial hemostatic agents are expensive, have many limitations and almost all of them are not antibacterial. Therefore, the development of an easy formulation of effective, rapid, antibacterial, and cheap hemostats is important. We have successfully developed chitosan based power which could be used to stop the bleeding rapidly.

Nano-emulsion:

We have formulated nano-emulsion by emulsion phase inversion method with particle size less than 200 nm. This nano-emulsion can be used as a topical formulation due to its controlled drug release property and rheology. The developed nano-emulsion-based topical formulation could be helpful in the topical delivery of drugs and/or vitamins in a sustained manner.